Recreation vehicles often require a fifth wheel landing gear support service and re-adjustment. These gears are equipped with the DC motor. Therefore, they are sometimes referred as DC motor gearboxes. However, being electrically operated, these gears are sensitive to any type of damage. You may face DC motor failure at any time if the system is not well accessorized. In such cases, motor repair or even replacement may be required. This post provides a step-by-step process of DC motor repair or replacement on the fifth wheel landing gear.

Step-by-Step Procedure of DC Motor Replacement on Fifth Wheel Landing Gear

The landing gear repair or replacement is performed in two phases. The first step is preparatory and the second stage is where the DC motor is actually repaired. The stage-wise steps followed in landing gear repair are as follows.

- Preparatory Stage: The preparatory stage of the fifth wheel landing gear repair focuses on the diagnosis and parts collection. In the preparatory stage, following steps are performed.

- Problem Diagnosis: There are two basic tests one should perform for problem diagnosis. At first, the driver must check if the leg is hitching and unhitching with the 5th gear. If not then it is a problem, which can be easily resolved by repairing the landing gear. If the vibration has increased and the car makes a choking noise while the DC motor assembly bounces, then it is a problem too. This problem needs DC motor assembly replacement. Sometimes, the failure may have been caused due to poor quality accessories.

- Parts Collection: Before starting repair or replacement, the operator must have all required parts, accessories, and mounting tools. In the case of replacement, the operator may require a new DC motor assembly, mounting brackets, power kit, parts kit, crank handle assemblies, and so on.

- DC Motor Replacement Stage: Once the preparatory stage is done, the operator begins with the DC motor replacement. The steps followed to replace DC motor assembly are detailed below.

- At first, the operator exposes the drive shaft that transmits power to the leg. This shaft is exposed by detaching the retaining bolts mounted on the sliding sheath. Once the bolts are off, the sheath can be slid back and forth. It exposes the drive shaft.

- The motor assembly is secured by a plastic retainer. It is supported by a screw and by taking the screw off, the DC motor assembly can be taken off the leg.

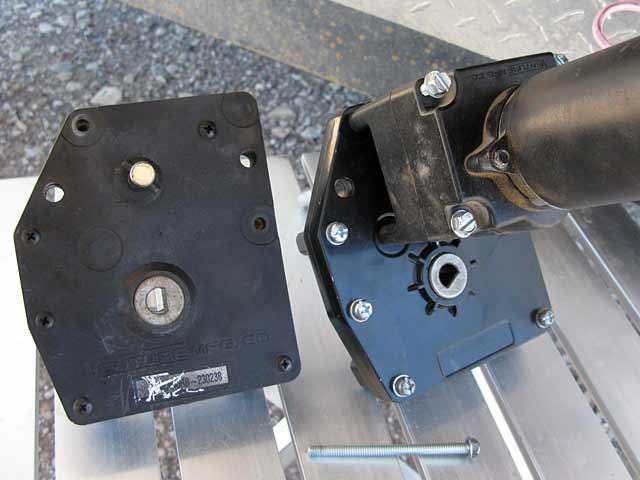

- The motor assembly is supposed to be slid off the drive shaft along with the gearbox.

- Once the DC motor and gearboxes are off, the operator detaches the DC motor from the gearbox. The motor is bolted on the gearbox with the help of four bolts, in which only two are required to be removed by the operator and the motor comes off.

- Once the motor is taken off, the operator replaces it with the new one that matches requirements.

- However, re-attachment of the motor assembly is performed by moving opposite leg shaft aside. Then a manual attachment or override shaft is inserted into the housing. The operator aligns the center of assembly and the significant location on the drive shaft. Then the assembly is center nutted.

- This completes the assembly process but then to finalize it, the component attachment is required to be done.

- The operator activates the landing gear switch to ensure the position of the motor assembly. Once the position is assured, the operator re-attaches the plastic retainer.

- The final step is to re-attach the opposite leg shaft and activating the landing gear switch by using a manual wrench. When this is done, the assembly is finalized with retainer bolts.

- At first, the operator exposes the drive shaft that transmits power to the leg. This shaft is exposed by detaching the retaining bolts mounted on the sliding sheath. Once the bolts are off, the sheath can be slid back and forth. It exposes the drive shaft.

Learn more on this topic in our related blog – Which are the Types of DC Gear Motor Controls?

Although the above-discussed process of changing DC motor n 5th wheel landing gear is easy to follow, it is always recommended to get it done by professionals. Also, it is important that you use a branded or quality replacement parts. Venture Mfg. Co offers RV and 5th wheel landing gear and 12 VDC power kit.